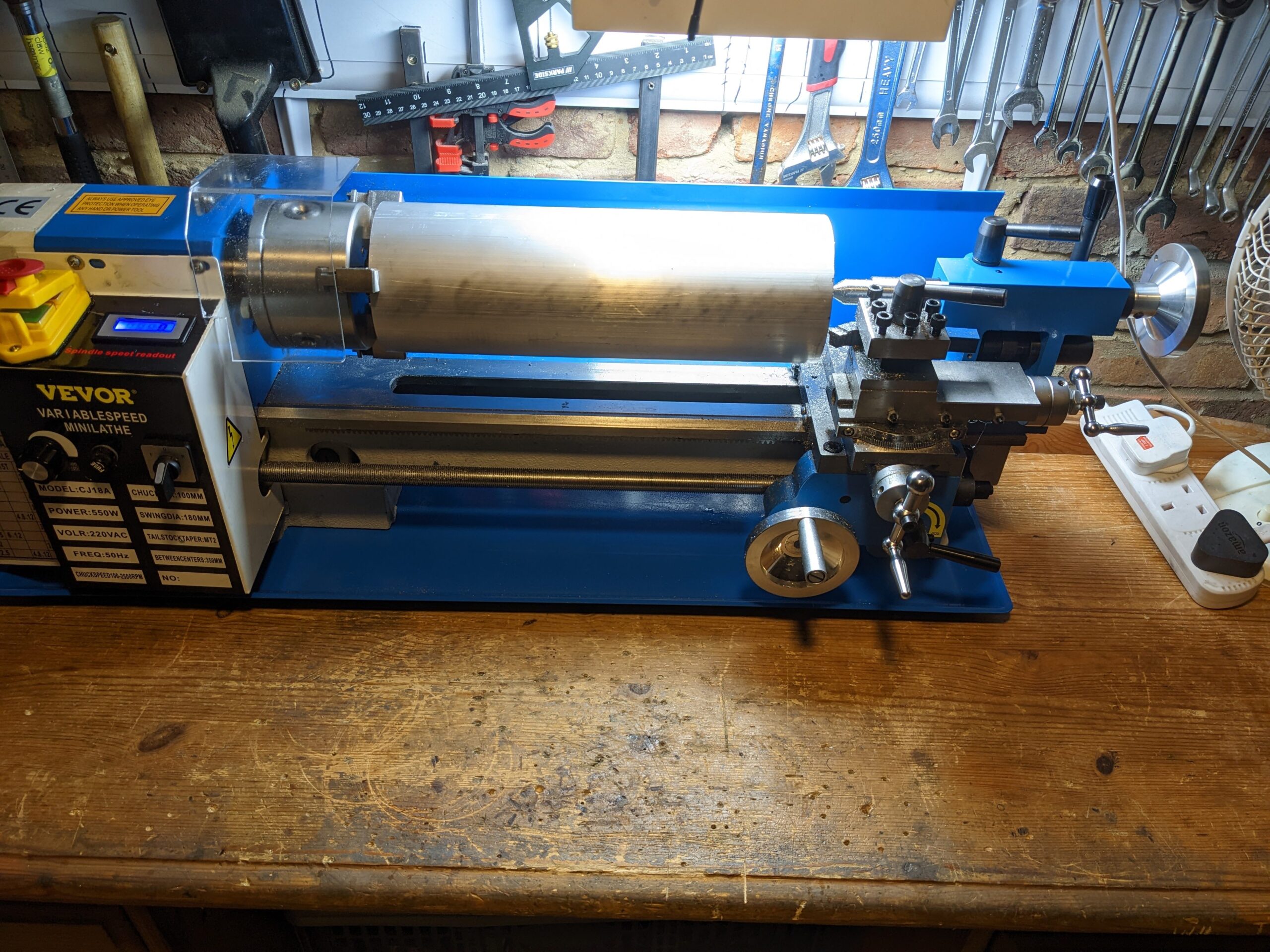

Article below is a part of the assembly process of the UHF duplexer – main article is HERE.

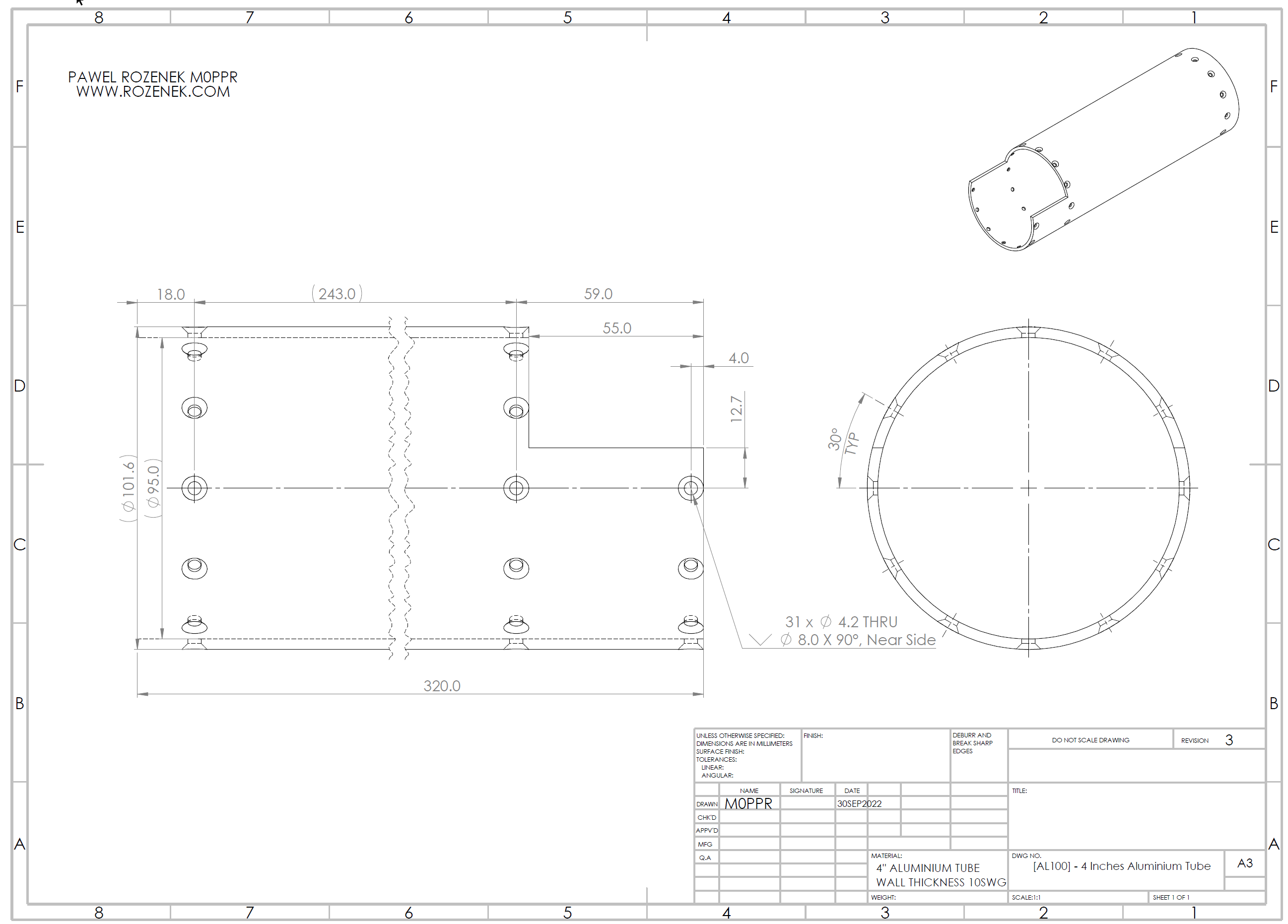

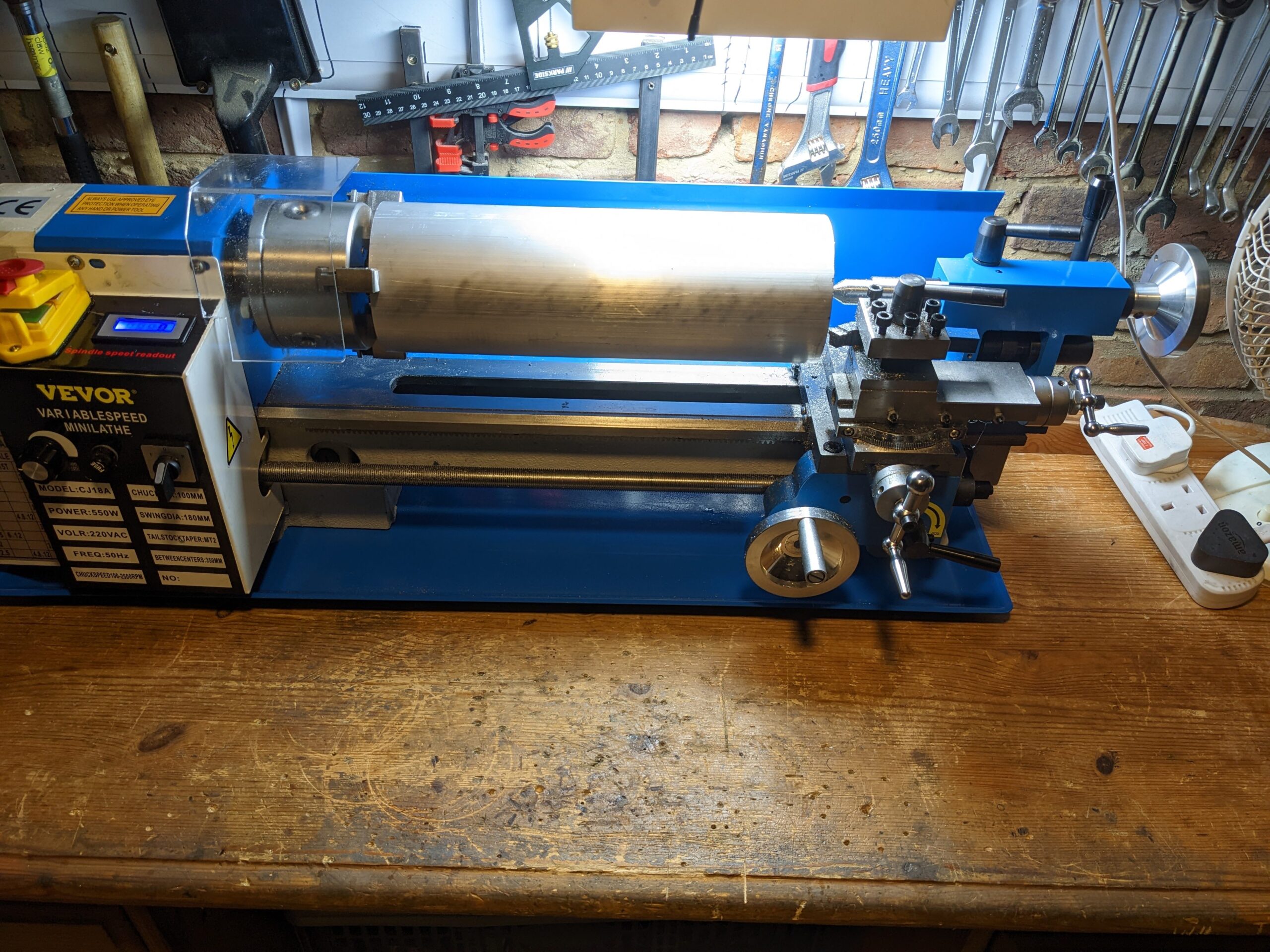

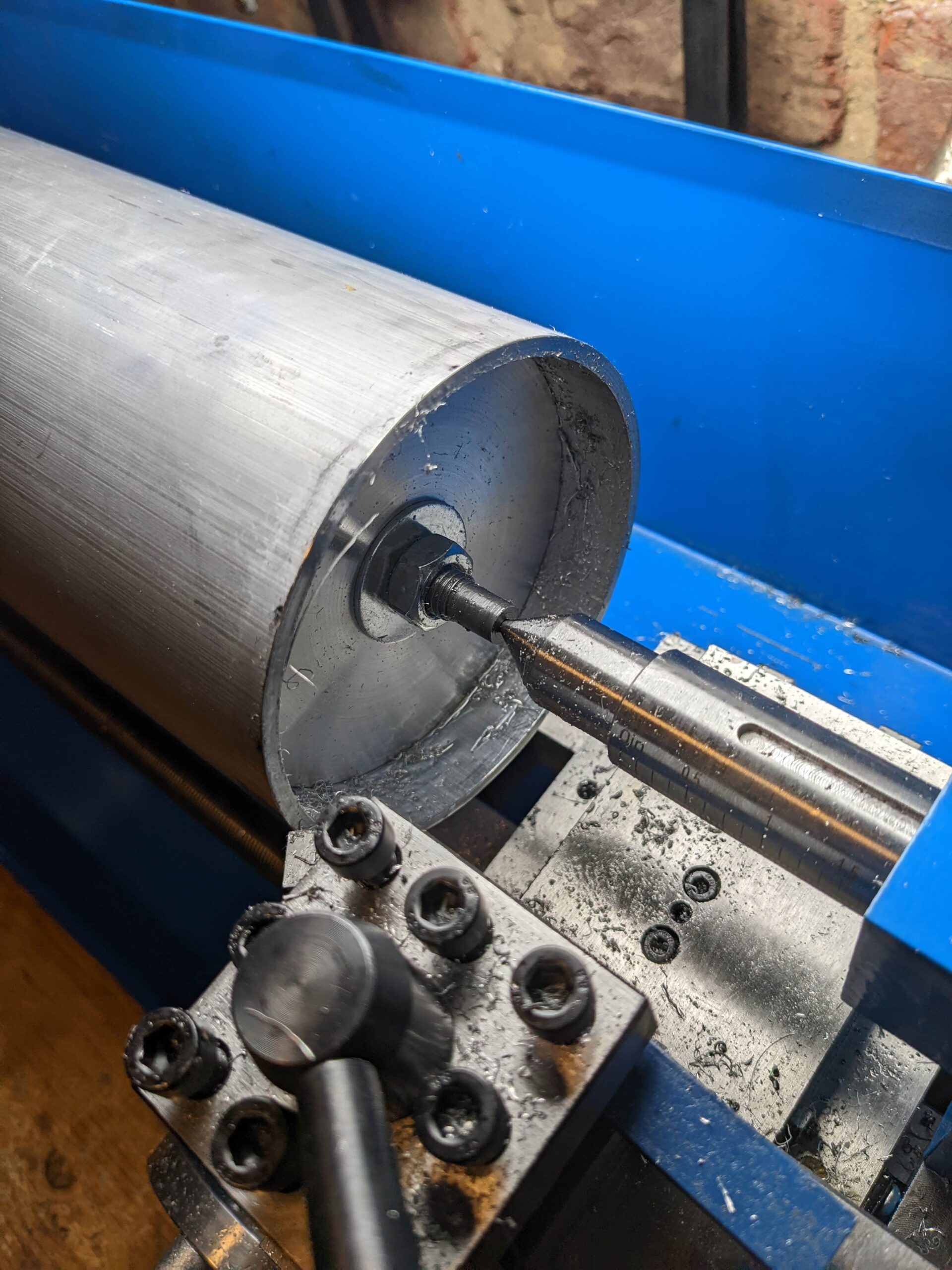

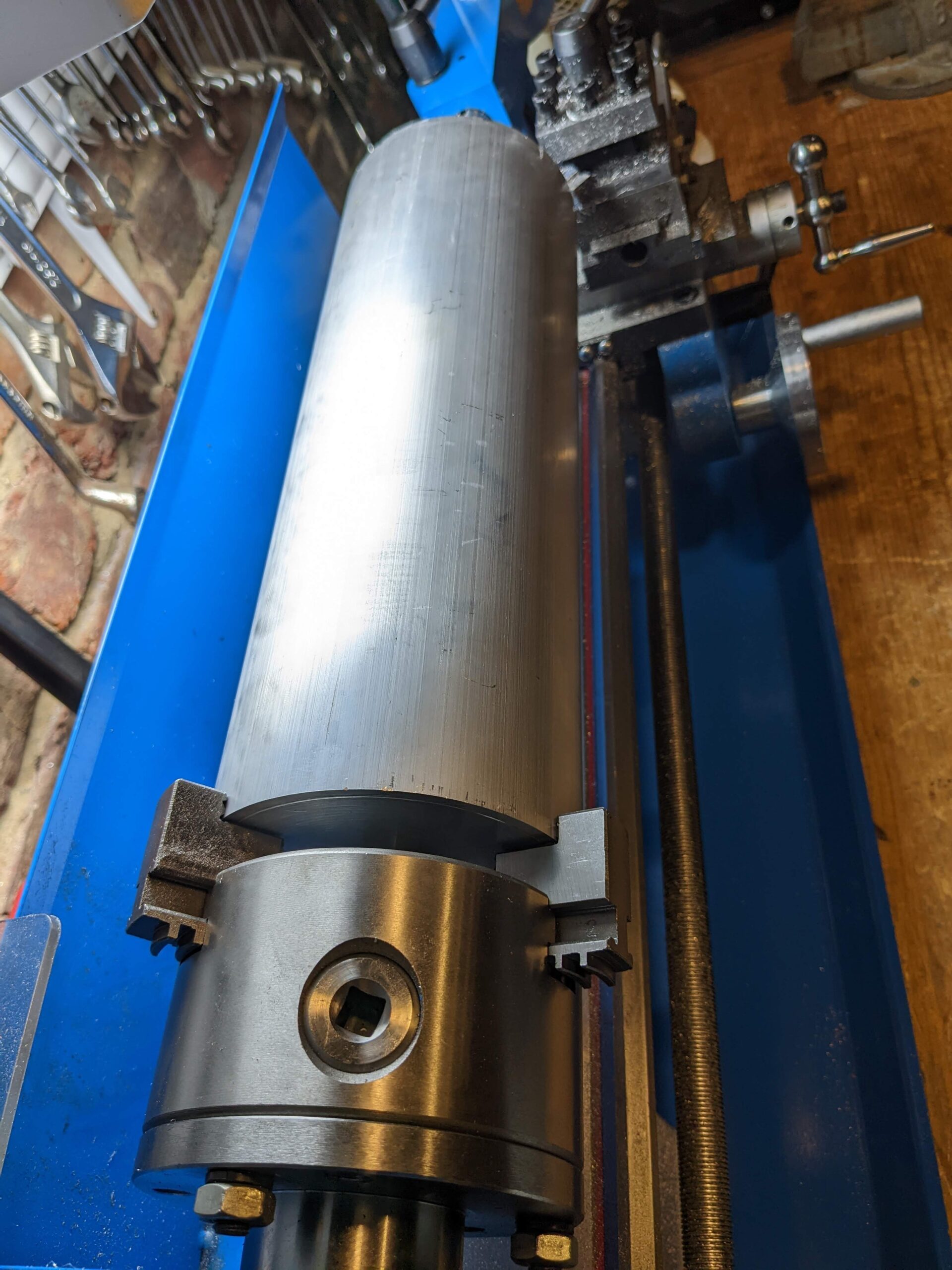

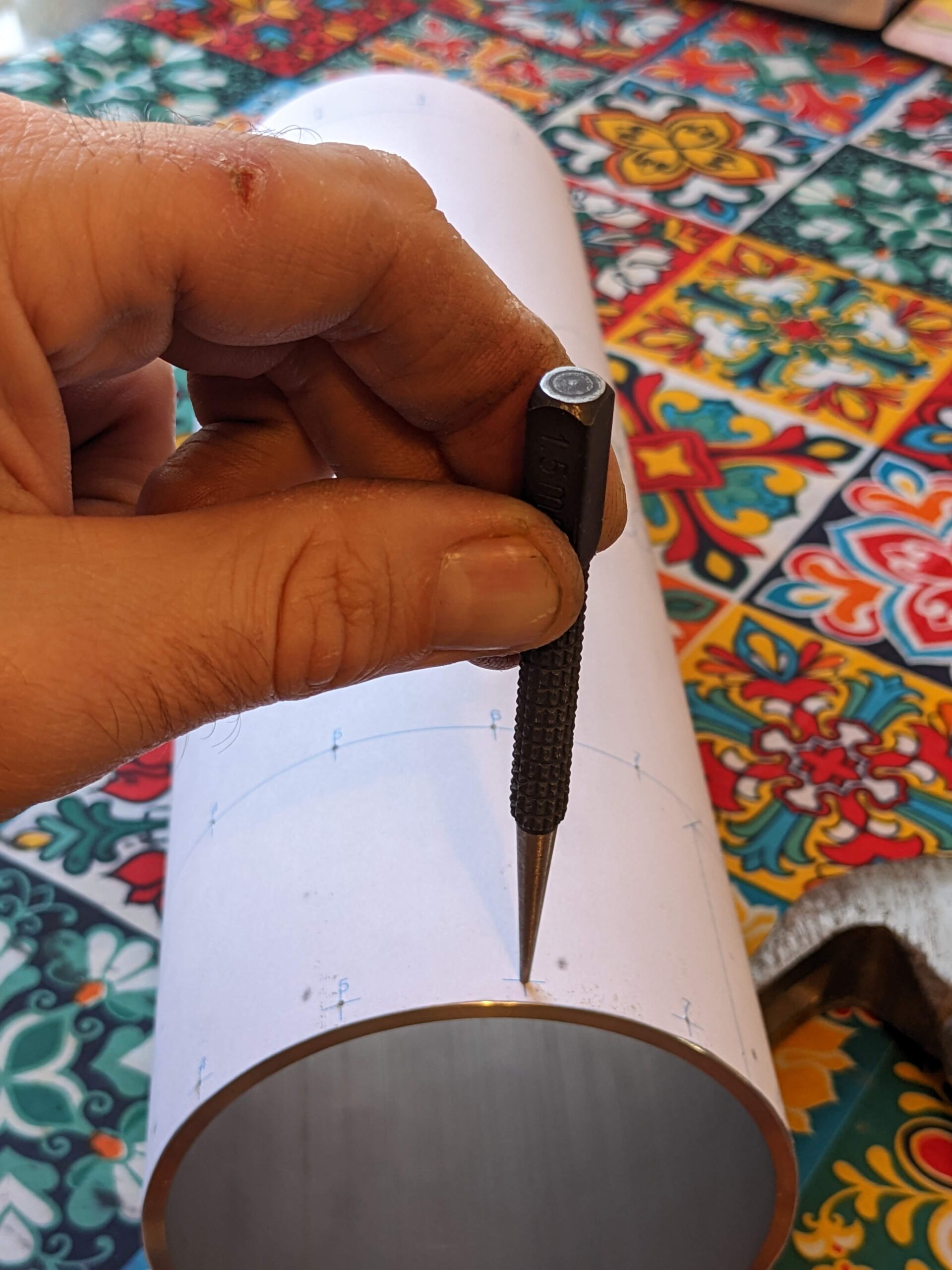

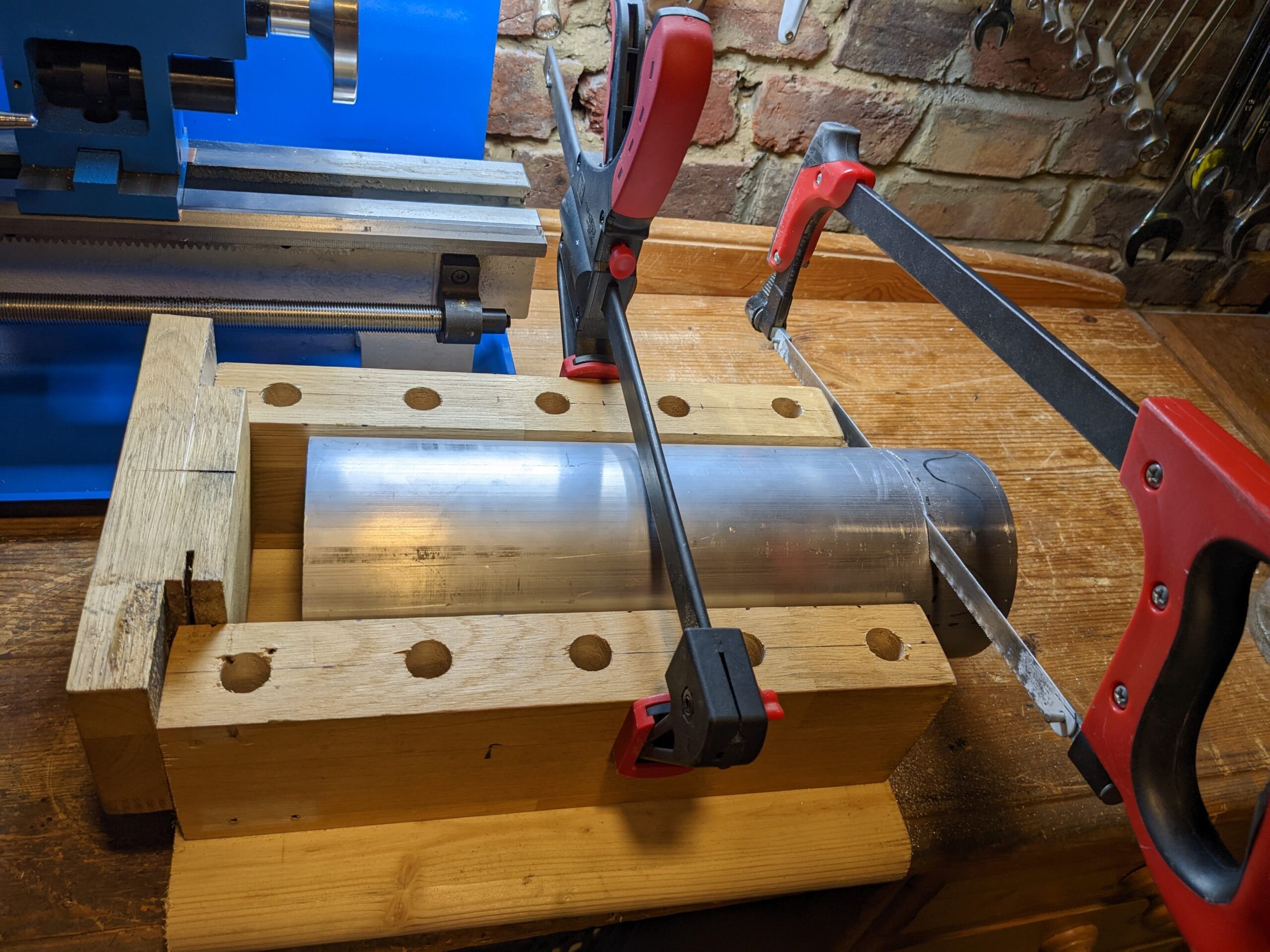

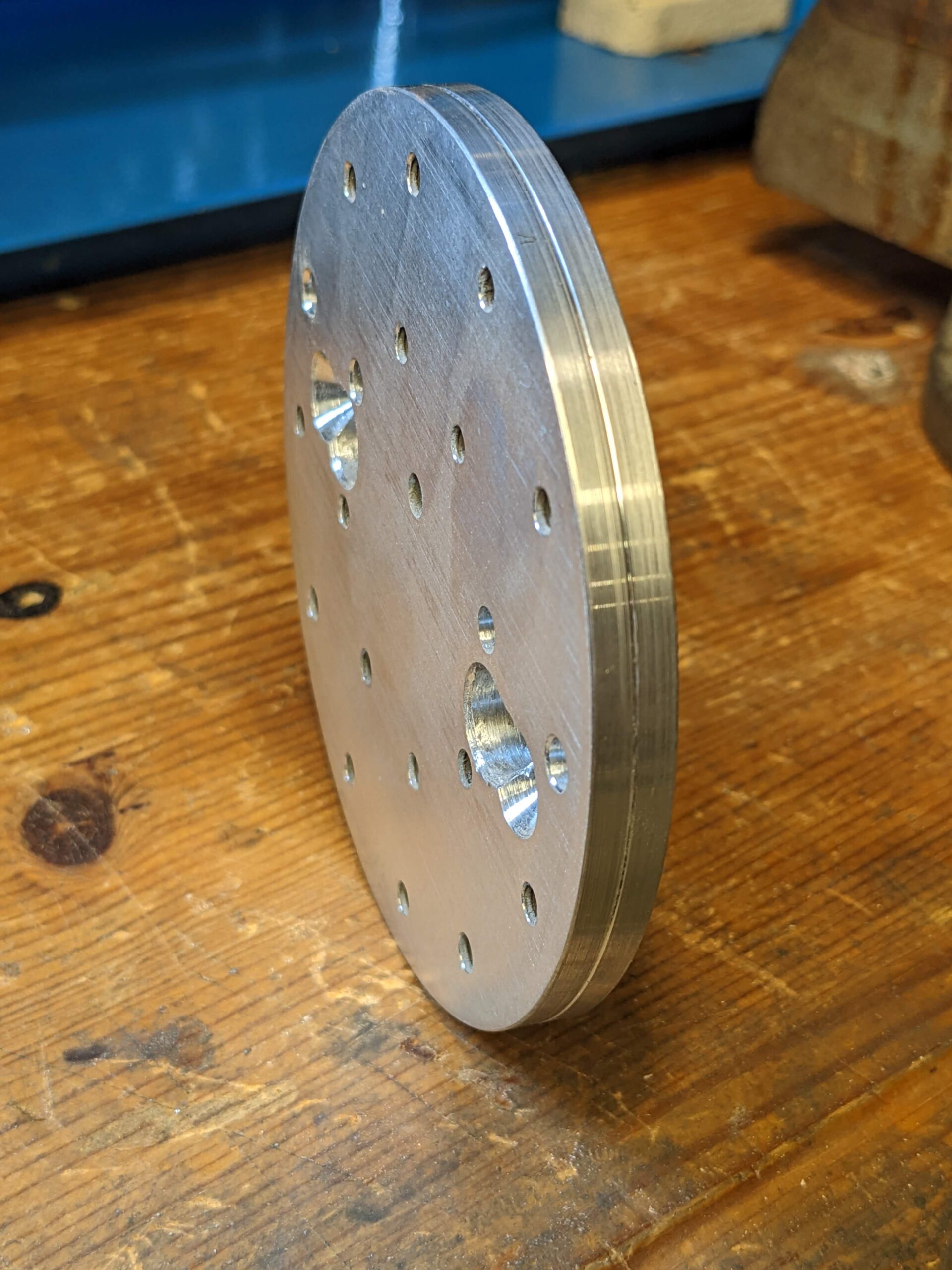

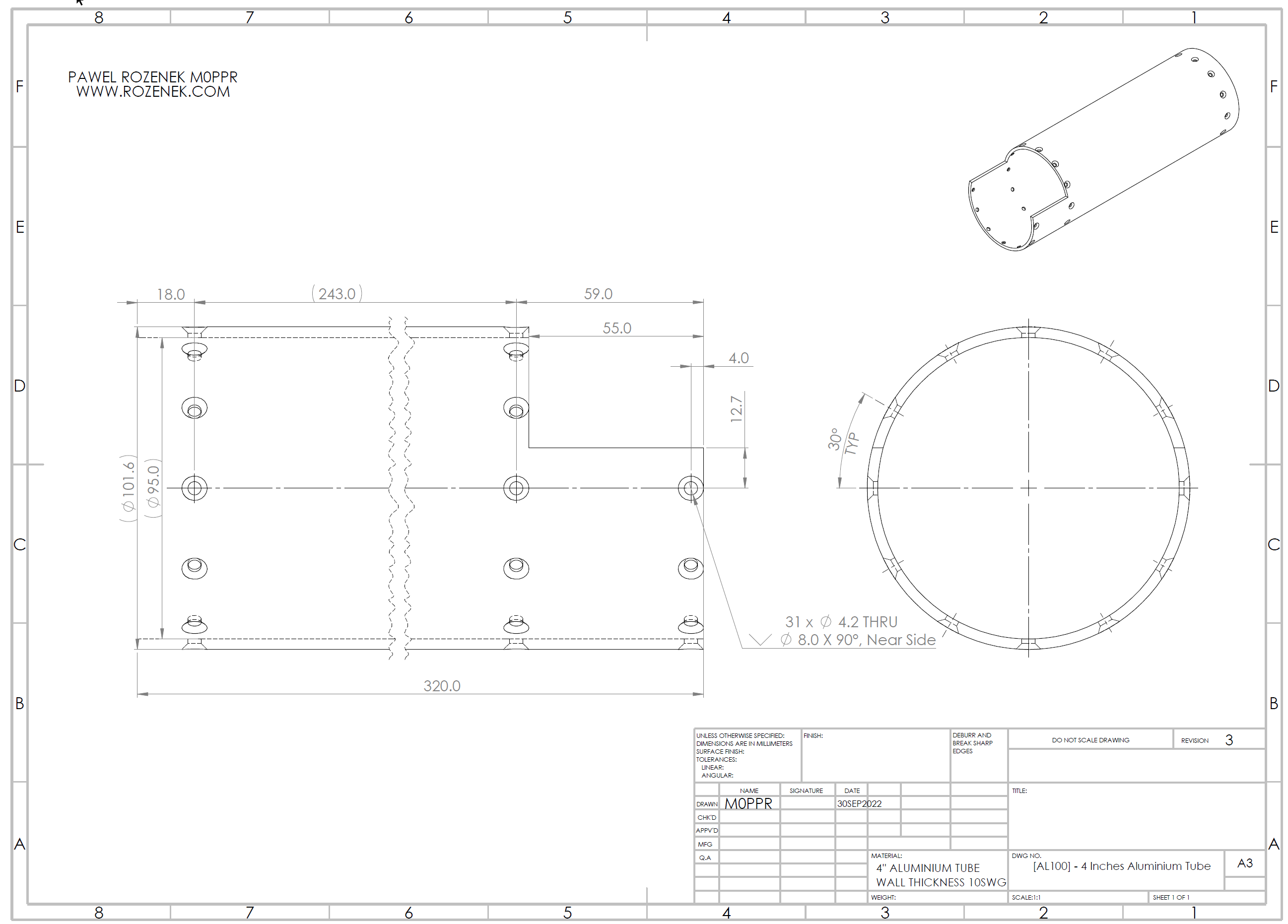

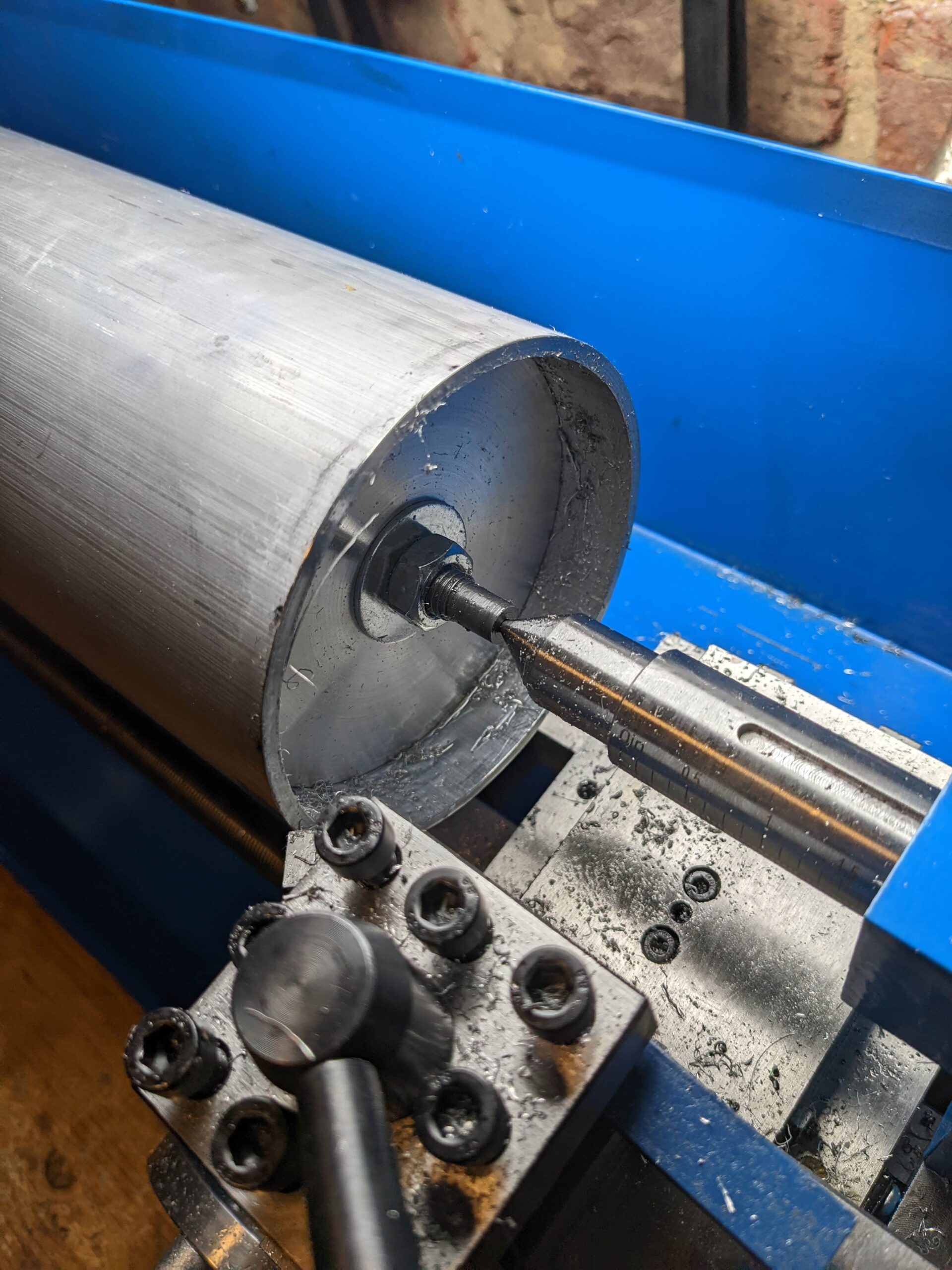

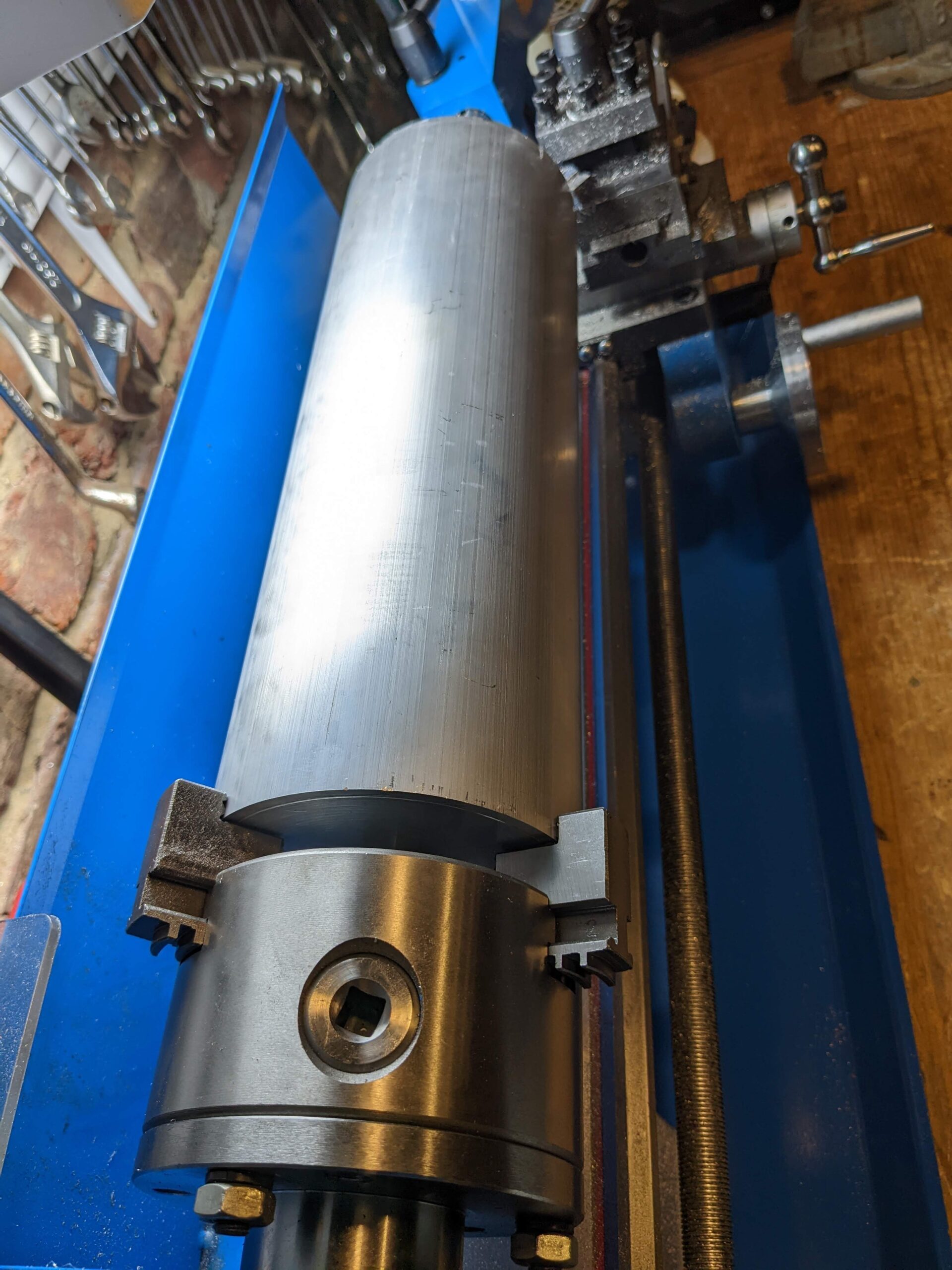

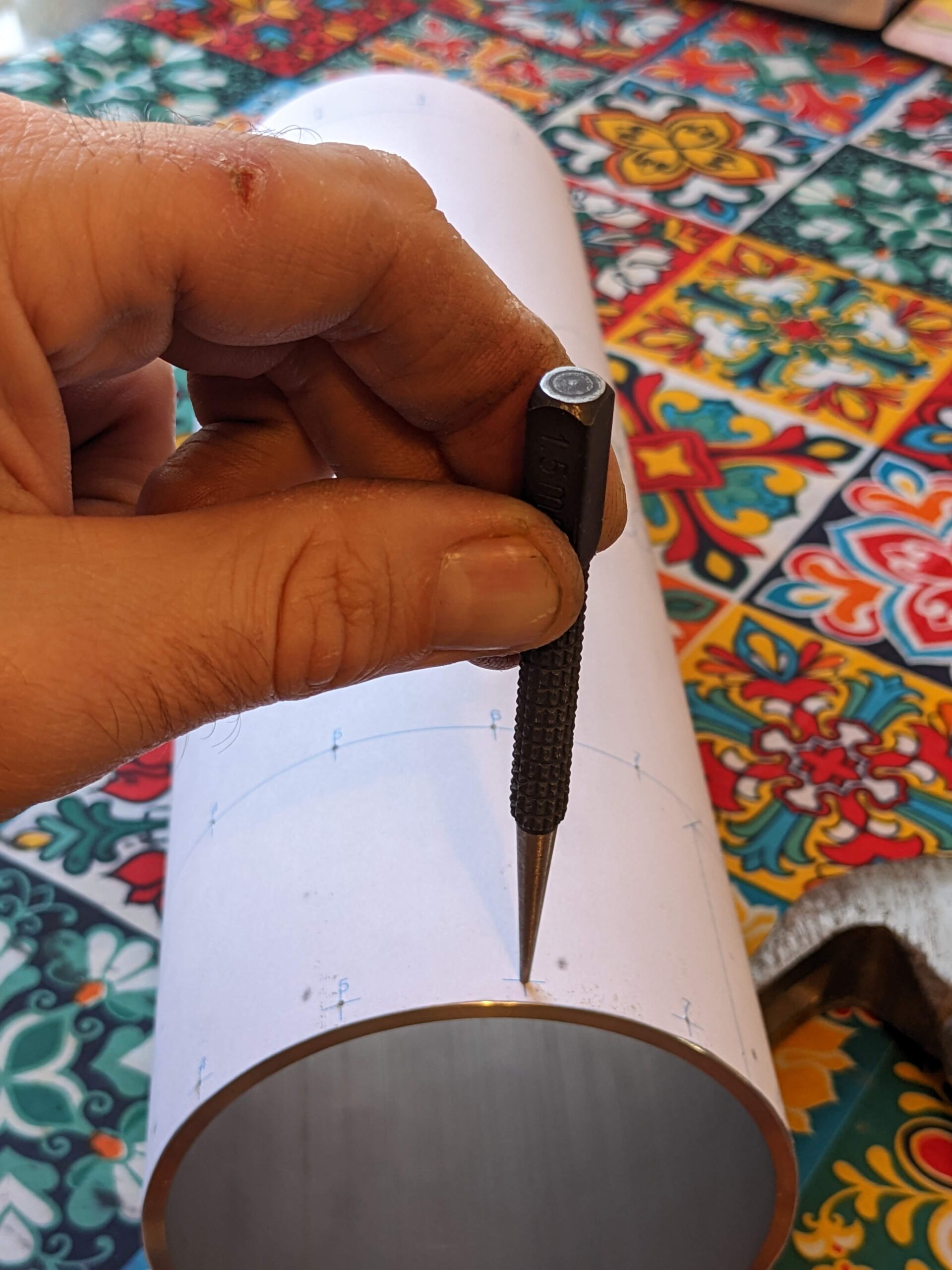

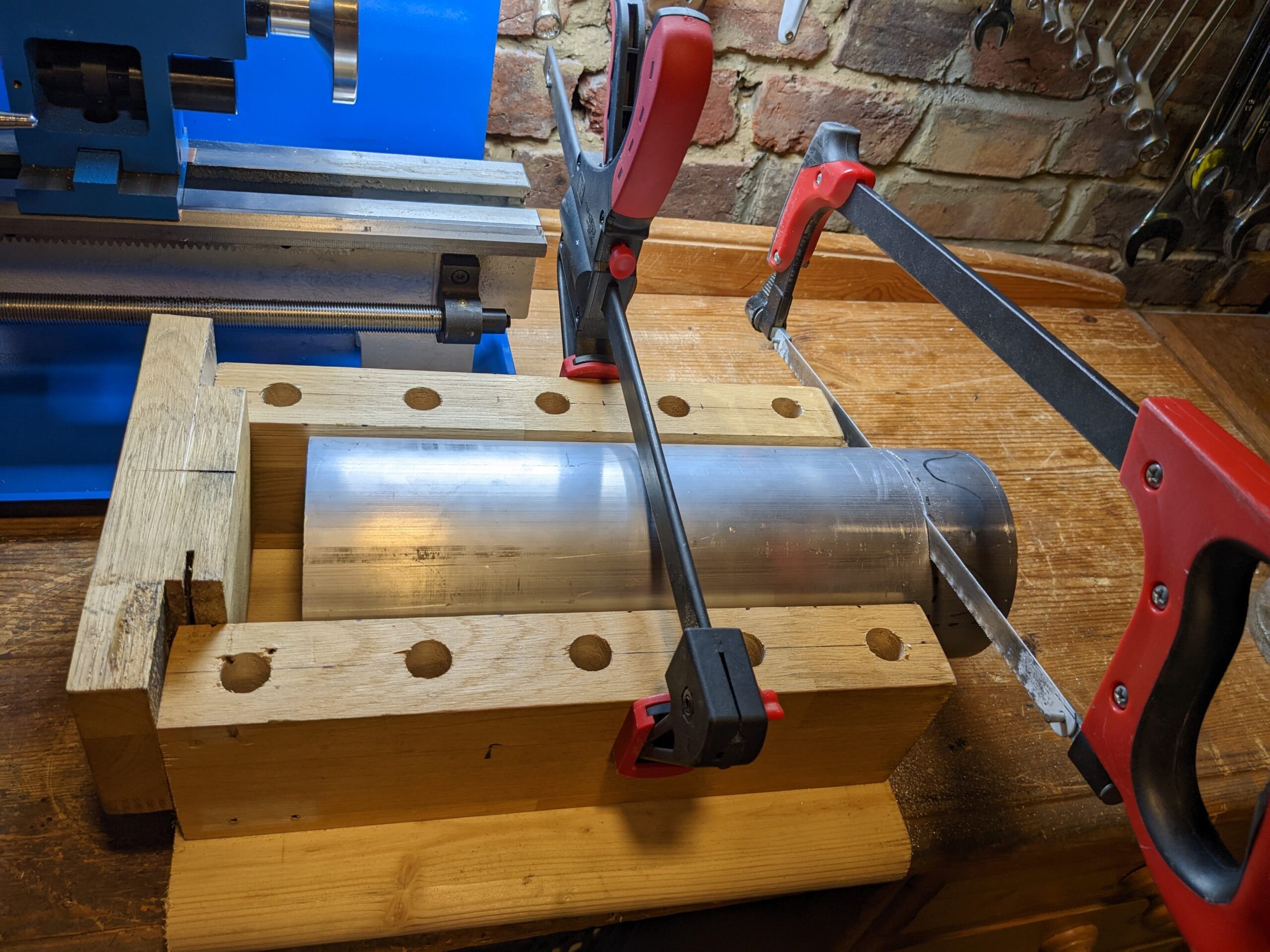

Drawing below shows a [AL100] – 4 Inches Aluminium Tube

Main purpose of the part: it is the main part of the cavity – all components are inside of the tube.

Pawel Rozenek's Website

Article below is a part of the assembly process of the UHF duplexer – main article is HERE.

Drawing below shows a [AL100] – 4 Inches Aluminium Tube

Main purpose of the part: it is the main part of the cavity – all components are inside of the tube.